Alkali activation of vein gold tailing wastes for manufacturing mortars

Activación alcalina de residuos de minería aurífera de veta para la fabricación de morteros

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Copyright statement

The authors exclusively assign to the Universidad EIA, with the power to assign to third parties, all the exploitation rights that derive from the works that are accepted for publication in the Revista EIA, as well as in any product derived from it and, in in particular, those of reproduction, distribution, public communication (including interactive making available) and transformation (including adaptation, modification and, where appropriate, translation), for all types of exploitation (by way of example and not limitation : in paper, electronic, online, computer or audiovisual format, as well as in any other format, even for promotional or advertising purposes and / or for the production of derivative products), for a worldwide territorial scope and for the entire duration of the rights provided for in the current published text of the Intellectual Property Law. This assignment will be made by the authors without the right to any type of remuneration or compensation.

Consequently, the author may not publish or disseminate the works that are selected for publication in the Revista EIA, neither totally nor partially, nor authorize their publication to third parties, without the prior express authorization, requested and granted in writing, from the Univeridad EIA.

Show authors biography

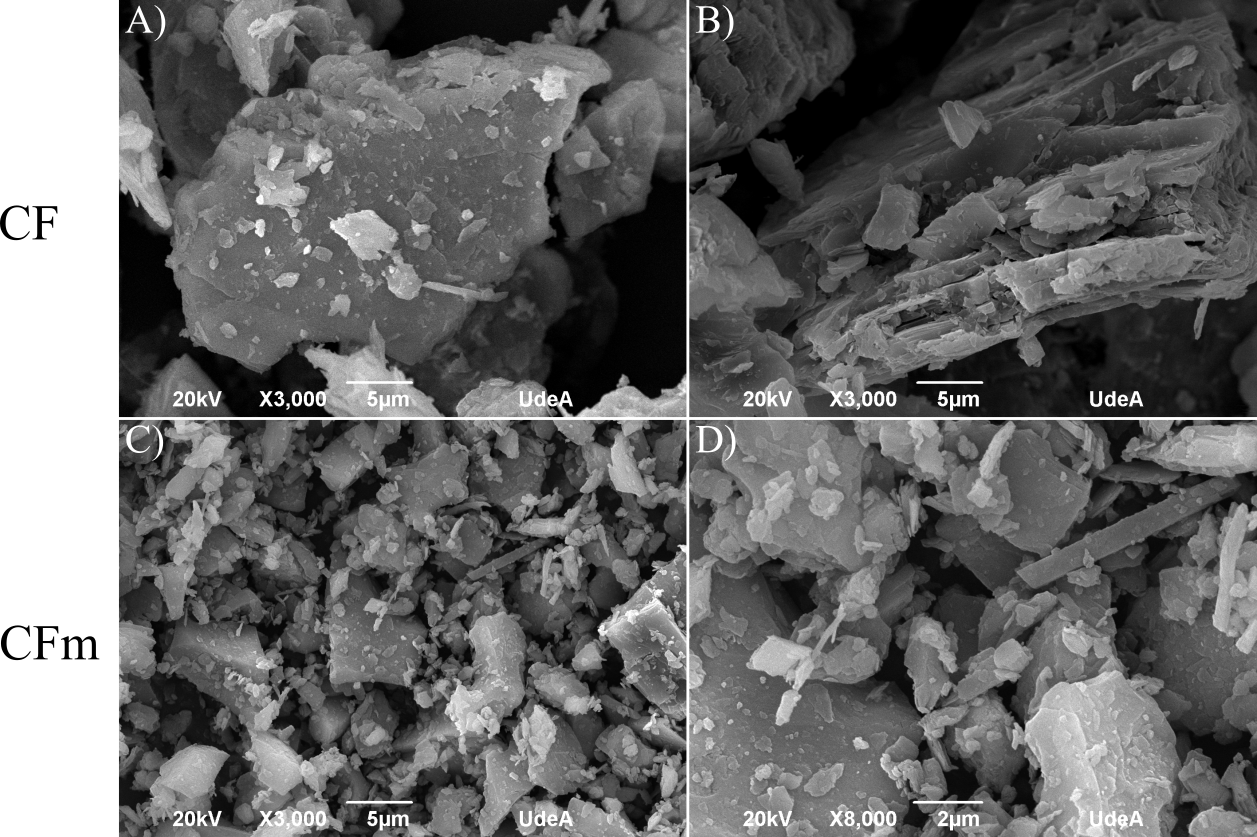

The mine tailings cause several environmental impacts, due to high and progressive mineral exploitation and waste management. Alkaline activation to manufacture building materials using waste as supplementary cementitious materials has been a widely used method. In this article, mortars with alkali-activated mine tailings has been studied. Vein gold tailing wastes, were activated by a mixture of NaOH and Na2SiO3 solution. Two types of mortars were analyzed to assess influence of particle size were manufactured, the first by using original granulometry tailing and the second with milled residue. In addition, each type of mortar was set at 24 and 80 °C. Crystalline phases in mortars were identified by X-ray diffraction (XRD), and the morphology of the fracture surfaces after the compression test was analyzed with scanning electron microscopy (SEM). The results show that the compressive strength of the specimens produced from milled residue was higher value in comparison with original granulometry specimens. In addition, setting temperature increase did not have an influence on the property evaluated.

Article visits 495 | PDF visits 355

Downloads

- Al-Shathr, B.; Shamsa, M.; Al-Attar, T. (2018). Relationship between amorphous silica in source materials and compressive strength of geopolymer concrete. MATEC Web of Conferences, 162, 02019. https://doi.org/10.1051/matecconf/201816202019

- ASTM C109/C109M - 16a. (2016). Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)1. https://doi.org/10.1520/C0109

- ASTM C33/C33M-18. (2018). Standard Specification for Concrete Aggregates. https://doi.org/10.1520/C0033

- ASTM D422-63. (2007). Standard test method for particle-size analysis of soils. https://doi.org/10.1520/D0422-63R07E02.2

- Comisión Asesora Permanente Para el Regimen de Construcciones Sismo Resistentes. (2010). NSR-10. Reglamento Colombiano de Construcción Sismo Resistente NSR-10, Ministerio de Ambiente, Vivienda y Desarrollo Territorial.

- Consoli, N. C.; Da Silva, A. P.; Nierwinski, H. P.; Sosnoski, J. (2018). Durability, strength, and stiffness of compacted gold tailings – cement mixes. Canadian Geotechnical Journal, 55(4), 486–494. https://doi.org/10.1139/cgj-2016-0391

- De Rossi, A.; Simão, L.; Ribeiro, M. J.; Novais, R. M.; Labrincha, J. A.; Hotza, D.; Moreira, R. (2019). In-situ synthesis of zeolites by geopolymerization of biomass fly ash and metakaolin. Materials Letters, 236, 644–648. https://doi.org/10.1016/j.matlet.2018.11.016

- Duan, P.; Yan, C.; Zhou, W.; Ren, D. (2016). Fresh properties, compressive strength and microstructure of fly ash geopolymer paste blended with iron ore tailing under thermal cycle. Construction and Building Materials, 118, 76–88. https://doi.org/10.1016/j.conbuildmat.2016.05.059

- Gitari, M. W.; Akinyemi, S. A.; Thobakgale, R.; Ngoejana, P. C.; Ramugondo, L.; Matidza, M.; Mhlongo, S. E.; Dacosta, F. A.; Nemapate, N. (2018). Physicochemical and mineralogical characterization of Musina mine copper and New Union gold mine tailings: Implications for fabrication of beneficial geopolymeric construction materials. Journal of African Earth Sciences, 137, 218–228. https://doi.org/10.1016/j.jafrearsci.2017.10.016

- Kinnunen, P.; Ismailov, A.; Solismaa, S.; Sreenivasan, H.; Räisänen, M. L.; Levänen, E.; Illikainen, M. (2018). Recycling mine tailings in chemically bonded ceramics – A review. Journal of Cleaner Production, 174, 634–649. https://doi.org/10.1016/j.jclepro.2017.10.280

- Kiventerä, J.; Golek, L.; Yliniemi, J.; Ferreira, V.; Deja, J.; Illikainen, M. (2016). Utilization of sulphidic tailings from gold mine as a raw material in geopolymerization. International Journal of Mineral Processing, 149, 104–110. https://doi.org/10.1016/j.minpro.2016.02.012

- Król, M.; Mozgawa, W. (2019). Zeolite layer on metakaolin-based support. Microporous and Mesoporous Materials, 282 (February), 109–113. https://doi.org/10.1016/j.micromeso.2019.03.028

- Lahoti, M.; Wong, K. K.; Yang, E. H.; Tan, K. H. (2018). Effects of Si/Al molar ratio on strength endurance and volume stability of metakaolin geopolymers subject to elevated temperature. Ceramics International, 44(5), 5726–5734. https://doi.org/10.1016/j.ceramint.2017.12.226

- Mermerdaş, K.; Manguri, S.; Nassani, D. E.; Oleiwi, S. M. (2017). Effect of aggregate properties on the mechanical and absorption characteristics of geopolymer mortar. Engineering Science and Technology an International Journal, 20(6), 1642–1652. https://doi.org/10.1016/j.jestch.2017.11.009

- Nazari, A., y Sanjayan, J. G. (2017). Handbook of Low Carbon Concrete. Oxford, Butterworth-Heinemann. https://www.elsevier.com/books/handbook-of-low-carbon-concrete/nazari/978-0-12-804524-4

- Pacheco-Torgal, F. (2014a). Eco-efficient construction and building materials research under the EU Framework Programme Horizon 2020. Construction and Building Materials, 51, 151–162. https://doi.org/10.1016/j.conbuildmat.2013.10.058

- Pacheco-Torgal, F; Labrincha, J. A.; Leonelli, C.; Palomo; A.; Chindaprasirt, P. (2014b). Handbook of Alkali-Activated Cements, Mortars and Concretes. Cambridge, Woodhead Publishing. https://www.elsevier.com/books/handbook-of-alkali-activated-cements-mortars-and-concretes/pacheco-torgal/978-1-78242-276-1

- Pacheco-Torgal, F.; Jalali, S.; Labrincha, J. A.; John, V. M. (2013). Eco-Efficient Concrete. Cambridge. Woodhead Publishing Limited. https://www.elsevier.com/books/eco-efficient-concrete/pacheco-torgal/978-0-85709-424-7.

- Palomo, A., Krivenko, P., Kavalerova, E., y Maltseva, O. (2018). A review on alkaline activation: New analytical perspectives. Materiales de Construcción, 64 (315), 1–23.

- Pandurangan, K.; Thennavan, M.; Muthadhi, A. (2018). Studies on effect of source of flyash on the bond strength of geopolymer concrete. Materials Today: Proceedings, 5(5), 12725–12733. https://doi.org/10.1016/j.matpr.2018.02.256

- Provis, J. L. (2017). Alkali-activated materials. Cement and Concrete Research. 114 (2), 40–48. https://doi.org/10.1016/j.cemconres.2017.02.009

- Provis, J. L.; Van Deventer, J. S. (2009). Geopolymers: Structures, processing, properties and industrial applications. Australia, Woodhead Publishing. https://www.elsevier.com/books/geopolymers/provis/978-1-84569-449-4.

- Ramujee, K.; Potharaju, M. (2017). Mechanical Properties of Geopolymer Concrete Composites. Materials Today: Proceedings, 4 (2), 2937–2945. https://doi.org/10.1016/j.matpr.2017.02.175

- Rend, M.; Fern, B. A.; Mart, M.; Andr, M.; José, T. A.; (2015). Desarrollo de nuevos cementos: “Cementos alcalinos y cementos híbridos”, México, Instituto Mexicano del Transporte, 73 p.

- Rivera, G. (2013). Dosificación de mezclas de concreto. Concreto simple. Colombia, pp. 169-197. Universidad del Cauca. https://www.academia.edu/13569512/CONCRETO_SIMPLE

- Solismaa, S.; Ismailov, A.; Karhu, M.; Sreenivasan, H.; Lehtonen, M.; Kinnunen, P.; Illikainen, M.;

- Räisänen, M. L. (2018). Valorization of Finnish mining tailings for use in the ceramics industry. Bulletin of the Geological Society of Finland, 90 (1), 33–54. https://doi.org/10.17741/bgsf/90.1.002

- Spin S.A. (2018). Especificaciones y certificado de calidad Flocsil, Colombia, Centro de investigación Spin S.A, 1 p.

- Wei, B., Zhang, Y., y Bao, S. (2017). Preparation of geopolymers from vanadium tailings by mechanical activation. Construction and Building Materials, 145, 236–242. https://doi.org/10.1016/j.conbuildmat.2017.03.234

- Wills, B. A.; Finch, J. A. (2016). Wills’ Mineral Processing Technology. Oxford, Butterworth-Heinemann. https://www.elsevier.com/books/wills-mineral-processing-technology/wills/978-0-08-097053-0