The Bovine leather skin substance analysis at different levels of concentrations of hydrolyzing agents in the liming and calera

El Análisis de sustancia piel de cueros bovinos a diferentes niveles de concentración de agentes hidrolizantes en el pelambre y calero

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Copyright statement

The authors exclusively assign to the Universidad EIA, with the power to assign to third parties, all the exploitation rights that derive from the works that are accepted for publication in the Revista EIA, as well as in any product derived from it and, in in particular, those of reproduction, distribution, public communication (including interactive making available) and transformation (including adaptation, modification and, where appropriate, translation), for all types of exploitation (by way of example and not limitation : in paper, electronic, online, computer or audiovisual format, as well as in any other format, even for promotional or advertising purposes and / or for the production of derivative products), for a worldwide territorial scope and for the entire duration of the rights provided for in the current published text of the Intellectual Property Law. This assignment will be made by the authors without the right to any type of remuneration or compensation.

Consequently, the author may not publish or disseminate the works that are selected for publication in the Revista EIA, neither totally nor partially, nor authorize their publication to third parties, without the prior express authorization, requested and granted in writing, from the Univeridad EIA.

Show authors biography

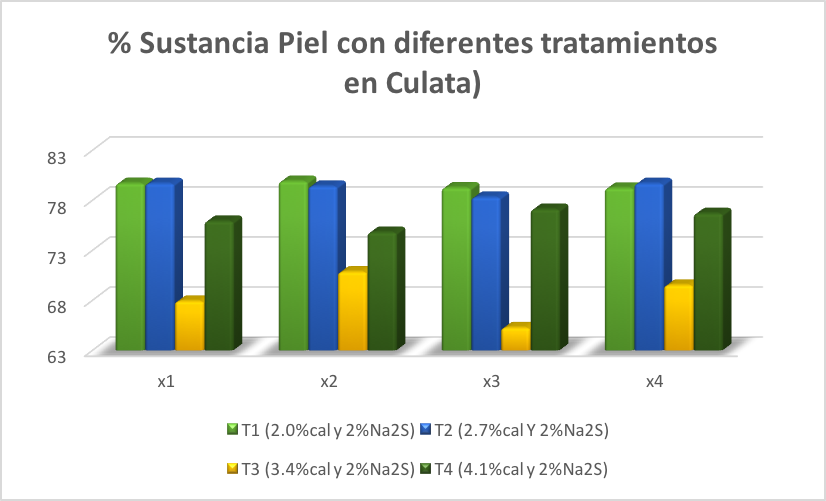

A study of Andean cattle skin was performed to determine the variation of skin substance (SP) produced by lime and sodium sulfide during the Liming and Calera stages using four different treatments (T). According to the ASTM D 2868-17, it is important to characterize the raw materials, followed by the tanning processes until obtaining samples of Wet Blue leather. Besides SP analysis and statistical treatment of the obtained data, sensory and physical-mechanical tests were carried out in the post-tanning stages. The results showed that SP at T1 (2.0% lime-2% Na2S) and T2 (2.7% lime-2% Na2S) produced the highest values; 79.5% and 79.3% respectively; with T3 (3.4% lime-2 % Na2S) and T4 (4.1% lime-2% Na2S) yielding 68.4% and 76.1%, respectively. The statistical analysis of the data evidenced that there is no significant differences between the means of T1 and T2. The results of the physical-mechanical and sensory tests directly relate to the trend of SP consumption in each treatment. The study carried out is aimed to recognize the direct relationship between the skin substance obtained in each treatment and the final product manufactured by the company, referred to the variability of the product to be obtained.

Article visits 574 | PDF visits 451

Downloads

- Acabados Abellán. (2014). “El curtido de las pieles: Un proceso con historia,” Acabados Abellán, Available: http://aca badosabellan.com/el-curtido-de-las-pieles-un-proceso-con-historia/

- AQEIC, “AQEIC,” Métodos de ensayos físicos. Available: http://www.aqeic.org/web/esp/.

- [ASTM International. (2017). “ASTM D2868 - 17 Standard Test Method for Nitrogen Content (Kjeldahl) and Hide Substance Content of Leather, Wet Blue and Wet White.” p. 6.

- BASF. (1985). “Vademécum para el Técnico en Curtición,” in Vademécum para el técnico en Curtición, 3rd ed., A. BASF, Ed. Ludwigshafen, pp. 25–30.

- Bennett, H. G. (2017). The Manufacture of Leather. Read Books Limited.

- Curtiduría Hidalgo, “CURTIDURÍA HIDALGO”. Available: https://www.hidalgocurtiduria.com/index.php/nosotros (Accedido sep. 3, 2020).

- E. Química Internacional para el Curtido, “Capitulo 04 Pelambre-Calero” Biblioteca Enciclopedia.. Available: https://www.quimicainternacional.com/biblioteca/enciclopedia/.

- Giulia, P. (2016). “La sostenibilità nell’industria conciaria,” tesis de pre grado, Dept. Econ Sci, UNIVERSITA’ DEGLI STUDI DI PADOVA, Padua, Italia. Available: https://core.ac.uk/download/pdf/89389162.pdf

- Hidalgo, L. C. (2013). “Diseño de la etapa de curtición de piel bovina con la utilización del extracto tánico y gálico del guarango caes alpiniaspinosa,” tesis de post grado, Fac. Sci, ESPOCH, Riobamba, Ecuador. Available: http://dspace.espoch.edu.ec/handle/123456789/3113.

- Jordán, M. (2011). “Obtención de colágeno por hidrólisis alcalina- enzimática del residuo de ‘wet blue’ en el proceso de curtición,” tesis de pre grado, Fac. Sci, ESPOCH, Riobamba, Ecuador. Available: http://dspace.espoch.edu.ec/handle/123456789/1630

- Luo, W.; Si, Y.; Wang, H.; Qin, Y. (2011). Huang, F.and Wang, C. “Spectrochimica Acta Part A : Molecular and Biomolecular Spectroscopy Leather material found on a 6th B . C . Chinese bronze sword : A technical study,” vol. 79, pp. 1630–1633.

- Manzo, G. (1999). “Chimica e tecnologia del cuoio,” in Chimica e tecnologia del cuoio, M. Service, Ed., pp. 113–125.

- Meléndrez, F. (2019). “Evaluación de diferentes niveles de silicato de sodio en combinación con guarango utilizados para la curtición de pieles caprinas,” tesis de post grado,Fac. Sci, ESPOCH, Riobamba, Ecuador. Available: http://dspace.espoch.edu.ec/handle/123456789/13287

- Melgar, D. (2000). Tecnología del Cuero- Procesos de Curtición Control de Calidad y Máquinas, Tomo 1. Hualhuas-Huancayo: MITINCI Industria.

- Moreira, J. (2002). i Prat and P. i Casanovas, “Química técnica de curtición,” in Química técnica de curtición, C. E. T. D. CETI, Ed. España: UNIVERSITAT POLITÉCNICA DE CATALUNYA, pp. 35–40.

- NTE INEN. (1984). NTE INEN 0936 Cuero de Ganado Vacuno. Terminología, vol. 0936. Ecuador.

- [Ozgunay, H.; Colak, S.; Mutlu, M. M.; Akyuz, F. (2007). “Characterization of Leather Industry Wastes,” Dep. Leather Eng. Fac. Eng. Ege Univ. 35100 Bornova, Izmir, Turkey, vol. 16, no. 6, pp. 867–873.

- Procter, H. R. (2017). The Principles of Leather Manufacture. (D.) Van Nostrand (and Co., Inc.), New York, NY, USA, p. 73. Available: http://www.gutenberg.org/files/57548/57548-h/57548-h.htm.

- Procter, H. R. (2019). A Text-book of Tanning: A treatise on the conversion of skins into leather, both practical and theoretical. Good Press, p. 139. Available: https://www.gutenberg.org/files/56601/56601-h/56601-h.htm

- Queirós, Â.; Silva, V. F. M.; Santos, T.; Crispim, A. (2018). “Optimization of bovine leather soaking process,” Rev. Piel. Incaltaminte, vol. 18, pp. 117–122.

- Rosu, L.; Varganici, C.; Crudu, A.; Rosu, D. (2018). “Influence of different tanning agents on bovine leather thermal degradation,” J. Therm. Anal. Calorim., vol. 134, no. 1, pp. 583–594.

- Sammarco, U. (2011). “Tecnología Conciaria,” in Tecnologia Conciaria, EDITMA, Ed., pp. 55–57.

- Schlichte, A. A. (2017). A Study of the Changes in Skins During Their Conversion into Leather. Trieste Publishing, p. 70.

- Soler J. i Solé, Procesos de Curtidos. Barcelona: UNIVERSITAT POLITÉCNICA DE CATALUNYA.

- Vallejo, J.; Almonacid, L.; Agudelo, R.; Ortíz, Ó. (2019). “Evaluation of alkaline-enzymatic hydrolysis to obtain hydrolyzed collagen from tanned leather shavings,” Rev. ION, vol. 32, no. 1, pp. 55–62.

- Wallace, E. L. (1931). “The hydrolysis of chestnut and quebracho tanned leathers by sulphuric acid,” Bur. Stand. J. Res., vol. 7, pp. 621–630.

- Zurita, G. (2016). “Análisis descriptivo de la sustentabilidad económica , social y ambiental de la industria del cuero del Ecuador,” Análisis de Caso, USFQ, Quito, Ecuador. Available: http://repositorio.usfq.edu.ec/bitstream/23000/5382/1/124320.pdf.