Computational fluid dynamics simulation in cone-bottom stirred tanks with a Rushton and pitchedblade turbines

Simulación dinámica computacional en tanques agitados de fondo cónico con turbina Rushton y de palas inclinadas

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Copyright statement

The authors exclusively assign to the Universidad EIA, with the power to assign to third parties, all the exploitation rights that derive from the works that are accepted for publication in the Revista EIA, as well as in any product derived from it and, in in particular, those of reproduction, distribution, public communication (including interactive making available) and transformation (including adaptation, modification and, where appropriate, translation), for all types of exploitation (by way of example and not limitation : in paper, electronic, online, computer or audiovisual format, as well as in any other format, even for promotional or advertising purposes and / or for the production of derivative products), for a worldwide territorial scope and for the entire duration of the rights provided for in the current published text of the Intellectual Property Law. This assignment will be made by the authors without the right to any type of remuneration or compensation.

Consequently, the author may not publish or disseminate the works that are selected for publication in the Revista EIA, neither totally nor partially, nor authorize their publication to third parties, without the prior express authorization, requested and granted in writing, from the Univeridad EIA.

Show authors biography

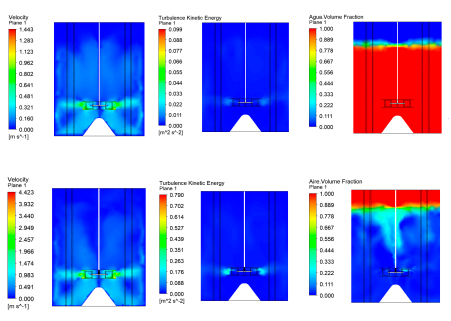

Computational Fluid Dynamics (CFD) is a tool frequently used for the optimization

and improvement of industrial processes. In this work, the CFD simulation is used for

analyzing the appropriate power in stirred-tank systems with three different types of cones

at the bottom of the tank and with two types of impellers: 45° pitch 4- bladed turbine (axial

impeller) and Rushton standard turbine (radial impeller). The simulation was carried out in

a stirred tank with a diameter of 27 cm and with different cone diameters and height ratios

are analyzed. Also, 4 rotation speeds (50, 100, 300, and 600 rpm) were evaluated to describe

the transition to turbulent states. Reynolds Stress Model (RSM) and the Moving Reference

Frame are used. The results show that the power decrease with the axial impeller when

this is operated at low Reynolds number values meanwhile the radial impeller presented an

increase in the values of power when the cone is introduced inside the tank. By increasing

the Reynolds number an exponential increase in the power volume of each impeller is

made. Also, the inclusion of a 4-impeller blade inclination between laminar and transition

shows a significant saving in power consumption and for turbulent regimes, the inclusion

of geometries in the bottom of the tank affects power consumption. Finally, the results are

validated using experimental data and show that the absolute deviations are below 4 %.

Article visits 373 | PDF visits 206

Downloads

- ANSYS. (2009a). Reynolds stress model [Online]. https://www.sharcnet.ca/Software/Fluent12/html/th/node79.htm (Accessed: 20 May 2022)

- ANSYS. (2009b). Standard k-ε - Model. [Online]. https://www.sharcnet.ca/Software/Fluent12/html/th/node58.htm (Accessed: 20 May 2022)

- Chudacek, M. W. (1985). Suspension in profiled mixing. Chemical Engineering Science, 40(3), pp. 385–392 https://doi.org/10.1016/0009-2509(85)85100-9

- Coroneo, M.; Montante, G.; Paglianti, A.; Magelli, F. (2011). CFD prediction of fluid flow and mixing in stirred tanks: Numerical issues about the RANS simulations. Computers and Chemical Engineering, 35(10), pp. 1959–1968 https://doi.org/10.1016/j.compchemeng.2010.12.007

- Daubert, T. E. (1998). Evaluated equation forms for correlating thermodynamic and transport properties with temperature. Industrial & Engineering Chemistry Research, 37(8), pp. 3260-3267 https://doi.org/10.1021/ie9708687

- Delgadillo, J. A.; Rajamani, R. K. (2005). A comparative study of three turbulence-closure models for the hydrocyclone problem. International Journal of Mineral Processing, 77(4), pp. 217–230 https://doi.org/10.1016/j.minpro.2005.06.007

- Dong, J.; Hu, B.; W Pacek, A.; Yang, X.; Miles, N. (2016). The Effect of Bottom Shape and Baffle Length on the Flow in Stirred Tanks in Turbulent and Transitional Flow. International Academy of Mechanical and Mechatronic Engineering, 10(9), pp. 1644–1653 https://doi.org/10.5281/zenodo.1126537

- Guha, D.; Ramachandran, P. A.; Dudukovic, M. P.; Derksen, J. J. (2008). Evaluation of Large Eddy Simulation and Euler-Euler CFD for Solids Flow Dynamics in a Stirred Tank Reactor. American Institute of Chemical Engineers AIChE, 54(3), pp. 766–788 https://doi.org/10.1002/aic.11417

- Joshi, J. B.; Nere, N. K.; Rane, C. V.; Murthy, B. N.; Mathpati, C. S.; Patwardhan, A. W.; Ranade, V. V. (2011a). CFD simulation of stirred tanks: Comparison of turbulence models. Part I: Radial flow impellers. Canadian Journal of Chemical Engineering, 89(1), pp. 23–82 https://doi.org/10.1002/cjce.20446

- Joshi, J. B.; Nere, N. K.; Rane, C. V.; Murthy, B. N.; Mathpati, C. S.; Patwardhan, A. W.; Ranade, V. V. (2011b). CFD simulation of stirred tanks: Comparison of turbulence models (Part II: Axial flow impellers, multiple impellers and multiphase dispersions). Canadian Journal of Chemical Engineering, 89(4), pp. 754–816 https://doi.org/10.1002/cjce.20465

- Lane, G. L.; Koh, P. T. L. (1997). CFD Simulation of a Rushton Turbine in a Baffled Tank, International Conference on Computational Fluid Dynamics in Mineral & Metal Processing and Power Generation. Clayton South, Victoria, Australia, pp. 377-386. https://www.cfd.com.au/cfd_conf97/papers/lan035.pdf

- Li, L.; Chen, N.; Xiang, K.; Xiang, B. (2018). CFD simulation of hydrodynamics characteristics in a tank stirred by a hollow self‐inducing impeller. Canadian Journal of Chemical Engineering, 96(8), pp. 1-12 https://doi.org/10.1002/cjce.23135

- Martínez, F. M.; Valencia, A. (2010). Estudio numérico de la fluidodinámica de un estanque de agitación utilizando método de mallas deslizantes (Tesis de pregrado en Ingeniería Civil), Chile, Facultad de Ciencias Físicas y Matemáticas Departamento de

- Ingeniería Mecánica, Chile, p. 90. https://repositorio.uchile.cl/handle/2250/103931

- McCabe, W. L.; Smith, J. C.; Harriot, P. (2007). Operaciones Unitarias En Ingeniería Química. McGraw Hill, pp. 260-281.

- Micale, G.; Montante, G.; Grisafi, F.; Brucato, A.; Godfrey, J. (2000). CFD Simulation of Particle Distribution in Stirred Vessels. Chemical Engineering Research and Design, 78(3), pp. 435-444 https://doi.org/10.1205/026387600527338

- Montante, G.; Lee, K. C.; Brucato, A.; Yianneskis, M. (2001). Numerical simulations of the dependency of flow pattern on impeller clearance in stirred vessels. Chemical Engineering Science, 56(12), pp. 3751-3770 https://doi.org/10.1016/S0009-2509(01)00089-6

- Motamedvaziri, S.; Armenante, P. M. (2012). Flow regimes and surface air entrainment in partially filled stirred vessels for different fill ratios. Chemical Engineering Science, 81, pp. 231–250 https://doi.org/10.1016/j.ces.2012.05.050

- Naeeni, S. K.; Pakzad, L. (2019). Droplet size distribution and mixing hydrodynamics in a liquid–liquid stirred tank by CFD modeling. International Journal of Multiphase Flow, 120, p. 103100 https://doi.org/10.1016/j.ijmultiphaseflow.2019.103100

- Ochieng, A., & Onyango, M. S. (2008). Homogenization energy in a stirred tank. Chemical Engineering and Processing: Process Intensification, 47(9-10), pp. 1853-1860. https://doi.org/10.1016/j.cep.2007.10.014

- Ochieng, A.; Onyango, M. S.; Kumar, A.; Kiriamiti, K.; Musonge, P. (2008). Mixing in a tank stirred by a Rushton turbine at a low clearance. Chemical Engineering and Processing: Process Intensification, 47(5), pp. 842-851 https://doi.org/10.1016/j.cep.2007.01.034

- Paul, E. L.; Atiemo-Obeng, V. A.; Kresta, S. M. (2004). Handbook of industrial mixing, New Jersey, John Wiley & Sons, Inc., pp. 359-375.

- Pukkella, A. K.; Vysyaraju, R.; Tammishetti, V.; Rai, B.; Subramanian, S. (2019). Improved mixing of solid suspensions in stirred tanks with interface baffles: CFD simulation and experimental validation. Chemical Engineering Journal, 358, pp. 621–633 https://doi.org/10.1016/j.cej.2018.10.020

- Sheikhi, N.; Najafi, M.; Enjilela, V. (2020). Modifying a meshless method to solving κ− ε turbulent natural convection heat transfer. International Journal of Modern Physics C, 31(01), p. 2050014 https://doi.org/10.1142/S012918312050014X

- Versteeg, H. K.; Malalasekera, W. (1995). An Introduction to Computational Fluid Dynamics: The volume finite method (1st ed.), London, Pearson education, pp. 1-40.

- Wu, H.; Patterson, G. K. (1989). Laser-Doppler measurements of turbulent-flow parameters in a stirred mixer. Chemical Engineering Science, 44(10), pp. 2207–2221 https://doi.org/10.1016/0009-2509(89)85155-3

- Wutz, J.; Waterkotte, B.; Heitmann, K.; Wucherpfennig, T. (2020). Computational fluid dynamics (CFD) as a tool for industrial UF/DF tank optimization. Biochemical Engineering Journal, 160, p. 107617 https://doi.org/10.1016/j.bej.2020.107617