Ceramic waste reuse and valorization alternatives: A review

Alternativas de reutilización y valorización de residuos cerámicos: una revisión

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Copyright statement

The authors exclusively assign to the Universidad EIA, with the power to assign to third parties, all the exploitation rights that derive from the works that are accepted for publication in the Revista EIA, as well as in any product derived from it and, in in particular, those of reproduction, distribution, public communication (including interactive making available) and transformation (including adaptation, modification and, where appropriate, translation), for all types of exploitation (by way of example and not limitation : in paper, electronic, online, computer or audiovisual format, as well as in any other format, even for promotional or advertising purposes and / or for the production of derivative products), for a worldwide territorial scope and for the entire duration of the rights provided for in the current published text of the Intellectual Property Law. This assignment will be made by the authors without the right to any type of remuneration or compensation.

Consequently, the author may not publish or disseminate the works that are selected for publication in the Revista EIA, neither totally nor partially, nor authorize their publication to third parties, without the prior express authorization, requested and granted in writing, from the Univeridad EIA.

Show authors biography

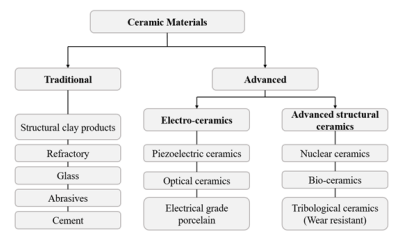

Ceramic materials account for the largest percentage of waste generated in the construction and demolition of concrete structures. Currently, this ceramic waste is disposed of in landfills, due to the lack of alternative disposal options and the lack of awareness of options for the reuse of these materials. This study aims to identify the existing alternatives and establish the potential for the reuse and valorization of ceramic waste. This analysis of alternatives for the reuse and valorization of ceramic waste is carried out through a bibliographic review focused on identifying the existing options for the reuse and valorization of ceramic waste. For each existing alternative, a brief description of the methodology used is made and the main results achieved in each study are highlighted. Based on the bibliographic review, some alternatives for the reuse of ceramic materials are presented. It was established that ceramic waste is currently used mainly in the formulation of concrete, manufacture of electrical insulators, extraction of alumina, and as a geological barrier to contain nuclear waste. In addition, based on the properties of ceramic materials, it was concluded that the potential applications for reuse include obtaining thermal insulators, abrasive materials, coral reef regeneration, and the elaboration of structures using additive manufacturing techniques. It was found that the most economically profitable option for the reuse and valorization of ceramic waste is the manufacture of concrete, while the most viable option is the manufacture of abrasive materials.

Article visits 667 | PDF visits 342

Downloads

- Alhabeeb, B. A., Mohammed, H. N., & Alhabeeb, S. A. (2021). Thermal insulators based on abundant waste materials. IOP Conference Series: Materials Science and Engineering, 1067(1), 012097. https://doi.org/10.1088/1757-899x/1067/1/012097

- Awoyera, P. O., Ndambuki, J. M., Akinmusuru, J. O., & Omole, D. O. (2018). Characterization of ceramic waste aggregate concrete. HBRC Journal, 14(3), 282–287. https://doi.org/10.1016/j.hbrcj.2016.11.003

- Blackett, G., Savory, E., Toy, N., Parke, G. A. R., Clark, M., & Rabjohns, B. (2008). An evaluation of the environmental burdens of present and alternative materials used for electricity transmission. Building and Environment, 43(7), 1326–1338. https://doi.org/10.1016/j.buildenv.2006.08.032

- Belhouchet, K., Bayadi, A., Belhouchet, H., & Romero, M. (2019). Improvement of mechanical and dielectric properties of porcelain insulators using economic raw materials. Boletín De La Sociedad Española De Cerámica y Vidrio, 58(1), 28–37. https://doi.org/10.1016/j.bsecv.2018.05.004

- Bhattacharyya, S., Das, S. K., & Mitra, N. K. (2005). Effect of titania on fired characteristics of triaxial porcelain. Bulletin of Materials Science, 28(5), 445–452. https://doi.org/10.1007/bf02711234

- Bhogilal, V. R., & Tejas, M. (2018). Pertinence of Ceramic Waste in Self Compacted Concrete as Partial Equivalent of Cement. International Research Journal of Engineering and Technology, 5(11), 344–349. ISSN: 2395-0056

- Bommisetty, J., Keertan, T. S., Ravitheja, A., & Mahendra, K. (2019). Effect of waste ceramic tiles as a partial replacement of aggregates in concrete. Materials Today: Proceedings, 19, 875–877. https://doi.org/10.1016/j.matpr.2019.08.230

- Burger, W., & Kiefer, G. (2021). Alumina, zirconia, and their composite ceramics with properties tailored for medical applications. Journal of Composites Science, 5(11), 306. https://doi.org/10.3390/jcs5110306

- Caligaris, R., Quaranta, N., Caligaris, M., & Benavidez, E. (2000). Materias Primas no tradicionales en la Industria Cerámica. Boletín De La Sociedad Española De Cerámica y Vidrio, 39(5), 623–626. https://doi.org/10.3989/cyv.2000.v39.i5.779

- Cicek, B., Karadagli, E., & Duman, F. (2018). Valorisation of boron mining wastes in the production of wall and floor tiles. Construction and Building Materials, 179, 232–244. https://doi.org/10.1016/j.conbuildmat.2018.05.182

- Contreras, J. (2014). Influencia de la inserción de nano-óxidos cerámicos sobre la microestructura y propiedades de una porcelana triaxial [Tesis de Doctorado, Universidad Autónoma de Nuevo León]. Repositorio institucional http://eprints.uanl.mx/11384/1/1080215587.pdf

- Cozzarini, L., Marsich, L., Ferluga, A., & Schmid, C. (2020). Life Cycle Analysis of a novel thermal insulator obtained from recycled glass waste. Developments in the Built Environment, 3, 100014. https://doi.org/10.1016/j.dibe.2020.100014

- Devanathan, R., Gao, F., & Sun, X. (2011). Challenges in modeling the degradation of ceramic waste forms, 1, 2–28. https://doi.org/10.2172/1043140

- El-Dieb, A. S., & Kanaan, D. M. (2018). Ceramic waste powder an alternative cement replacement – characterization and evaluation. Sustainable Materials and Technologies, 17, 1–11. https://doi.org/10.1016/j.susmat.2018.e00063

- El País. (2019, April 24). Ice proyecta instalación de megaestructura de arrecife artificial en Costa del Pacífico. Diario Digital Nuestro País. Retrieved December 1, 2022, from https://www.elpais.cr/2019/04/23/ice-proyecta-instalacion-de-megaestructura-de-arrecife-artificial-en-costa-del-pacifico/

- European Commission. (2018). Energy Performance of Buildings directive. Energy performance of buildings directive. Retrieved December 1, 2022, from https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en

- Fassbinder, G. (2002). A New Ceramic Body Concept for High Strength High Voltage Insulators. CFI Ceramic Forum International, 79, E17-E19. Disponible en: https://www.researchgate.net/publication/287903598_A_new_ceramic_body_concept_for_high_strength_high_voltage_insulators

- Garza, J. (2019, April 25). Gobierno propone Construcción de Mega Arrecife artificial en el Pacífico. Periódico La República. Retrieved December 1, 2022, from https://www.larepublica.net/noticia/gobierno-propone-construccion-de-mega-arrecife-artificial-en-el-pacifico

- Gress, R. I., & Leshchenko, N. P. (1969). Increasing the porcelain pitchers content in high-voltage porcelain bodies. Glass and Ceramics, 26(4), 249–252. https://doi.org/10.1007/bf00676453

- Henao, L. F., & López, M. E. (2017). Caracterización y aprovechamiento de residuos sólidos de la industria electrocerámica, como fuente de extracción de alúmina. Revista Colombiana De Materiales, (10), 43–55. Recuperado de: https://revistas.udea.edu.co/index.php/materiales/article/view/328003

- Hind, A. R., Bhargava, S. K., & Grocott, S. C. (1999). The surface chemistry of Bayer Process Solids: A review. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 146(1-3), 359–374. https://doi.org/10.1016/s0927-7757(98)00798-5

- Huang, B., Li, C., Zhang, Y., Ding, W., Yang, M., Yang, Y., Zhai, H., Xu, X., Wang, D., Debnath, S., Jamil, M., Li, H. N., Ali, H. M., Gupta, M. K., & Said, Z. (2021). Advances in fabrication of ceramic corundum abrasives based on sol–gel process. Chinese Journal of Aeronautics, 34(6), 1–17. https://doi.org/10.1016/j.cja.2020.07.004

- Hur, H., Jin Park, Y., Kim, D.-H., & Wan Ko, J. (2022). Material extrusion for ceramic additive manufacturing with polymer-free ceramic precursor binder. Materials & Design, 221, 110930. https://doi.org/10.1016/j.matdes.2022.110930

- Huseien, G. F., Sam, A. R., Shah, K. W., & Mirza, J. (2020). Effects of ceramic tile powder waste on properties of self-compacted alkali-activated concrete. Construction and Building Materials, 236, 117-574. https://doi.org/10.1016/j.conbuildmat.2019.117574

- INMR. (2021). Testing ageing of porcelain insulators. Retrieved November 16, 2022, from https://www.inmr.com/testing-ageing-of-porcelain-insulators/

- Jain, P., Gupta, R., & Chaudhary, S. (2022). A literature review on the effect of using ceramic waste as supplementary cementitious material in cement composites on workability and compressive strength. Materials Today: Proceedings, 65, 871–876. https://doi.org/10.1016/j.matpr.2022.03.453

- Jerônimo, V. L., Meira, G. R., & da Silva, L. C. (2018). Performance of self-compacting concretes with wastes from heavy ceramic industry against corrosion by chlorides. Construction and Building Materials, 169, 900–910. https://doi.org/10.1016/j.conbuildmat.2018.03.034

- Juan, A., Medina, C., Guerra, I., Morán, J., Aguado, P., Sánchez, M., Frias, M., & Rodríguez, O. (2010). Re-use of ceramic wastes in construction, 1, 197–214. Ceramic Materials. IntechOpen. https://doi.org/10.5772/intechopen.83933

- Kannan, D. M., Aboubakr, S. H., EL-Dieb, A. S., & Reda Taha, M. M. (2017). High performance concrete incorporating ceramic waste powder as large partial replacement of Portland Cement. Construction and Building Materials, 144, 35–41. https://doi.org/10.1016/j.conbuildmat.2017.03.115

- Keleştemur, O., Yildiz, S., Gökçer, B., & Arici, E. (2014). Statistical analysis for freeze–thaw resistance of cement mortars containing marble dust and glass fiber. Materials & Design, 60, 548–555. https://doi.org/10.1016/j.matdes.2014.04.013

- Keshavarz, Z., & Mostofinejad, D. (2019). Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete. Construction and Building Materials, 195, 218–230. https://doi.org/10.1016/j.conbuildmat.2018.11.033

- Khalil, N. M. (2014). Exploitation of the ceramic wastes for the extraction of Nano Aluminum Oxide Powder. Journal of Industrial and Engineering Chemistry, 20(5), 3663–3666. https://doi.org/10.1016/j.jiec.2013.12.063

- Khattab, R. M., Wahsh, M. M. S., & Khalil, N. M. (2012). Preparation and characterization of porous alumina ceramics through starch consolidation casting technique. Ceramics International, 38(6), 4723–4728. https://doi.org/10.1016/j.ceramint.2012.02.057

- Kostadinović, D., Jovanović, M., Bakić, V., Stepanić, N., & Todorović, M. (2022). Experimental investigation of summer thermal performance of the green roof system with mineral wool substrate. Building and Environment, 217, 109061. https://doi.org/10.1016/j.buildenv.2022.109061

- Lassinantti, M., Mugoni, C., Guandalini, S., Cattini, A., Mazzini, D., Alboni, C., & Siligardi, C. (2018). Glass recycling in the production of low-temperature stoneware tiles. Journal of Cleaner Production, 197, 1531–1539. https://doi.org/10.1016/j.jclepro.2018.06.264

- Lakhdar, Y., Tuck, C., Binner, J., Terry, A., & Goodridge, R. (2021). Additive Manufacturing of Advanced Ceramic Materials. Progress in Materials Science, 116, 100736. https://doi.org/10.1016/j.pmatsci.2020.100736

- Liebermann, J. (2012). High-voltage insulators: Basics and trends for producers, users, and students (1) Fraunhofer Institute for Ceramic Technologies and Systems. ISBN: 9783877352083

- Liu, T., Zhang, J., Wu, J., Liu, J., Li, C., Ning, T., Luo, Z., Zhou, X., Yang, Q., & Lu, A. (2019). The utilization of electrical insulators waste and red mud for fabrication of partially vitrified ceramic materials with high porosity and high strength. Journal of Cleaner Production, 223, 790–800. https://doi.org/10.1016/j.jclepro.2019.03.162

- Marciano, S., Mugnier, N., Clerin, P., Cristol, B., & Moulin, P. (2006). Nanofiltration of Bayer Process Solutions. Journal of Membrane Science, 281(1-2), 260–267. https://doi.org/10.1016/j.memsci.2006.03.040

- Matjie, R. H., Bunt, J. R., & Van Heerden, J. H. P. (2005). Extraction of alumina from coal fly ash generated from a selected low rank bituminous South African coal. Minerals Engineering, 18(3), 299–310. https://doi.org/10.1016/j.mineng.2004.06.013

- Matteucci, F., Dondi, M., & Guarini, G. (2002). Effect of soda-lime glass on sintering and technological properties of porcelain stoneware tiles. Ceramics International, 28(8), 873–880. https://doi.org/10.1016/s0272-8842(02)00067-6

- Mavrič, A., Valant, M., Cui, C., & Wang, Z. M. (2019). Advanced applications of amorphous alumina: From Nano to bulk. Journal of Non-Crystalline Solids, 521, 119493. https://doi.org/10.1016/j.jnoncrysol.2019.119493

- Meena, R. V., Jain, J. K., Chouhan, H. S., & Beniwal, A. S. (2022). Use of waste ceramics to produce sustainable concrete: A Review. Cleaner Materials, 4, 100085. https://doi.org/10.1016/j.clema.2022.100085

- Meng, Y., Gong, G., Wei, D., & Xie, Y. (2016). In situ high temperature X-ray diffraction study on high strength aluminous porcelain insulator with the AL2O3-SiO2-K2O-NA2O system. Applied Clay Science, 132-133, 760–767. https://doi.org/10.1016/j.clay.2016.07.014

- Meng, Y., Gong, G., Wu, Z., Yin, Z., Xie, Y., & Liu, S. (2012). Fabrication and microstructure investigation of ultra-high-strength porcelain insulator. Journal of the European Ceramic Society, 32(12), 3043–3049. https://doi.org/10.1016/j.jeurceramsoc.2012.04.015

- Merga, A., Murthy, H. C. A., Amare, E., Ahmed, K., & Bekele, E. (2019). Fabrication of electrical porcelain insulator from ceramic raw materials of Oromia Region, Ethiopia. Heliyon, 5(8). https://doi.org/10.1016/j.heliyon.2019.e02327

- Mert, H. H., & Mert, M. S. (2021). Design of N-octadecane-based form-stable composite phase change materials embedded in porous nano alumina for thermal energy storage applications. Journal of Thermal Analysis and Calorimetry, 147(8), 4925–4934. https://doi.org/10.1007/s10973-021-10886-0

- Mitchell, A., Lafont, U., Hołyńska, M., & Semprimoschnig, C. (2018). Additive Manufacturing - a review of 4D printing and future applications. Additive Manufacturing, 24, 606–626. https://doi.org/10.1016/j.addma.2018.10.038

- Moraes, E., Sangiacomo, L., P. Stochero, N., Arcaro, S., R. Barbosa, L., Lenzi, A., Siligardi, C., & Novaes de Oliveira, A. P. (2019). Innovative thermal and acoustic insulation foam by using recycled ceramic shell and expandable styrofoam (EPS) wastes. Waste Management, 89, 336–344. https://doi.org/10.1016/j.wasman.2019.04.019

- Morocutti, T., Berg, T., Muhr, M., & Godel, G. (2012). Developments of high voltage porcelain post-insulators. 2012 IEEE International Symposium on Electrical Insulation. https://doi.org/10.1109/elinsl.2012.6251497

- Nepomuceno, M. C. S., Isidoro, R. A. S., & Catarino, J. P. G. (2018). Mechanical performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste. Construction and Building Materials, 165, 284–294. https://doi.org/10.1016/j.conbuildmat.2018.01.052

- Owoeye, S. S., Toludare, T. S., Isinkaye, O. E., & Kingsley, U. (2019). Influence of waste glasses on the physico-mechanical behavior of Porcelain Ceramics. Boletín De La Sociedad Española De Cerámica y Vidrio, 58(2), 77–84. https://doi.org/10.1016/j.bsecv.2018.07.002

- Palaniyappan, S., Veiravan, A., Kaliyamoorthy, R., & Kumar, V. (2021). Sustainable solution to low-cost alternative abrasive from electric ceramic insulator waste for use in abrasive water jet machining. https://doi.org/10.21203/rs.3.rs-606563/v1

- Papailiou, K. O., & Schmuck, F. (2013). Silicone composite insulators. Power Systems, 1, 197-283. doi:10.1007/978-3-642-15320-4

- Piyaphanuwat, R., & Asavapisit, S. (2017). Utilization ceramic wastes from porcelain ceramic industry in lightweight aggregate concrete. International Journal of Environmental Science and Development, 8(5), 342–346. https://doi.org/10.18178/ijesd.2017.8.5.975

- Portella, K. F., Joukoski, A., Franck, R., & Derksen, R. (2006). Reciclagem Secundária de Rejeitos de porcelanas elétricas em estruturas de concreto: Determinação do Desempenho Sob Envelhecimento Acelerado. Cerâmica, 52(323), 155–167. https://doi.org/10.1590/s0366-69132006000300008

- Rodríguez, E. A., Niño, C. J., Contreras, J. E., Vázquez, F. J., López-Perales, J. F., Aguilar-Martínez, J. A., Puente-Ornelas, R., & Lara-Banda, M. (2019). Influence of incorporation of fired porcelain scrap as partial replacement of quartz on properties of an electrical porcelain. Journal of Cleaner Production, 233, 501–509. https://doi.org/10.1016/j.jclepro.2019.05.403

- Ruys, A. (2019). Refractory and other specialist industrial applications of alumina. Alumina Ceramics, 473–499. https://doi.org/10.1016/b978-0-08-102442-3.00015-4

- Sabaa, Z. M., & Fahad, B. M. (2018). Glass and porcelain waste as abrasives investigated at different conditions. IOP Conference Series: Materials Science and Engineering, 454, 012117. https://doi.org/10.1088/1757-899x/454/1/012117

- Sabaa, Z. M., & Fahad, B. M. (2019). Utilization of construction waste to developing an abrasive material. Journal of Engineering and Applied Sciences, 14(8), 2582–2587. https://doi.org/10.36478/jeasci.2019.2582.2587

- Said, S., Mikhail, S., & Riad, M. (2019). Recent progress in preparations and applications of Meso-porous alumina. Materials Science for Energy Technologies, 2(2), 288–297. https://doi.org/10.1016/j.mset.2019.02.005

- Sekar, T., Ganesan, N., & Nampoothiri, N. (2011). Studies on strength characteristics on utilization of waste materials as coarse aggregate in concrete. International Journal of Engineering Science and Technology. 3(7), 5436–5440. ISSN: 0975-5462

- Sepehri, A., & Sarrafzadeh, M.-H. (2018). Effect of nitrifiers community on fouling mitigation and nitrification efficiency in a membrane bioreactor. Chemical Engineering and Processing - Process Intensification, 128, 10–18. https://doi.org/10.1016/j.cep.2018.04.006

- Shah, K. W., & Huseien, G. F. (2020). Utilizing ceramic wastes in the concrete industry. Recycled Ceramics in Sustainable Concrete, 33–48. https://doi.org/10.1201/9781003120292-3

- Siddique, S., Shrivastava, S., & Chaudhary, S. (2018a). Evaluating resistance of fine bone china ceramic aggregate concrete to sulphate attack. Construction and Building Materials, 186, 826–832.https://doi.org/10.1016/j.conbuildmat.2018.07.138

- Siddique, S., Shrivastava, S., Chaudhary, S., & Gupta, T. (2018b). Strength and impact resistance properties of concrete containing fine bone china ceramic aggregate. Construction and Building Materials, 169, 289–298. https://doi.org/10.1016/j.conbuildmat.2018.02.213

- Siddique, S., Chaudhary, S., Shrivastava, S., & Gupta, T. (2019). Sustainable utilisation of ceramic waste in concrete: Exposure to adverse conditions. Journal of Cleaner Production, 210, 246–255. https://doi.org/10.1016/j.jclepro.2018.10.231

- Sun, J., Ye, D., Zou, J., Chen, X., Wang, Y., Yuan, J., Liang, H., Qu, H., Binner, J., & Bai, J. (2023). A review on additive manufacturing of ceramic matrix composites. Journal of Materials Science & Technology, 138, 1–16. https://doi.org/10.1016/j.jmst.2022.06.039

- Tam, V. W. Y., Soomro, M., & Evangelista, A. C. (2018). A review of recycled aggregate in concrete applications (2000–2017). Construction and Building Materials, 172, 272–292. https://doi.org/10.1016/j.conbuildmat.2018.03.240

- Tikul, N. (2014). Assessing environmental impact of small and medium ceramic tile manufacturing enterprises in Thailand. Journal of Manufacturing Systems, 33(1), 1–6. https://doi.org/10.1016/j.jmsy.2013.12.002

- Zengrong, Y., Xinghua, Z., & Kangming, M. (2013). Patente de China No. CN102951897A. Washington, DC: U.S. Patent and Trademark Office. https://patents.google.com/patent/CN102951897A/en#patentCitations