Procedure for determination of geometric quality of tooth profile in in spur tooth cylindrical gears

Procedimiento para la determinación de la calidad geométrica del perfil del diente en engranajes cilíndricos de dientes rectos

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Copyright statement

The authors exclusively assign to the Universidad EIA, with the power to assign to third parties, all the exploitation rights that derive from the works that are accepted for publication in the Revista EIA, as well as in any product derived from it and, in in particular, those of reproduction, distribution, public communication (including interactive making available) and transformation (including adaptation, modification and, where appropriate, translation), for all types of exploitation (by way of example and not limitation : in paper, electronic, online, computer or audiovisual format, as well as in any other format, even for promotional or advertising purposes and / or for the production of derivative products), for a worldwide territorial scope and for the entire duration of the rights provided for in the current published text of the Intellectual Property Law. This assignment will be made by the authors without the right to any type of remuneration or compensation.

Consequently, the author may not publish or disseminate the works that are selected for publication in the Revista EIA, neither totally nor partially, nor authorize their publication to third parties, without the prior express authorization, requested and granted in writing, from the Univeridad EIA.

Show authors biography

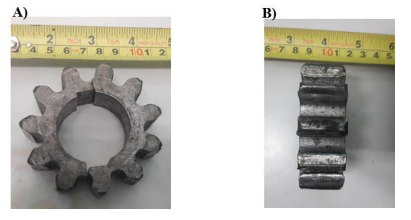

The research objective is to establish a procedure that integrates the process statistical

control with computer-aided design and engineering tools, to determine the geometric

quality of tooth profile in spur tooth cylindrical gears (STCG), obtained from the machining

process by chip removal. Therefore, a simulation was carried out, by the Finite Element

Method, to the STCG with modification and without geometric modification of profile to

evaluate its resistance to bending. It was evident that, the machining process is under

adequate statistical control, there are no deviations in tooth profile coefficient values. The

decrease in the stress state at the tooth base with modified geometry was verified. It was

concluded that the proposed procedure allowed evaluating the initial conception of the

design up to the dimensional control to quality assess of manufacturing process.

Article visits 205 | PDF visits 123

Downloads

- Budynas, R.; Nisbett, K. (2012). Diseño en ingeniería mecánica de Shigley, México, McGraw-Hill/Interamericana. https://pdfcoffee.com/diseo-en-ingenieria-mecanica-de-shigley-9na-edicion-richard-g-budynas-2-pdf-free.html

- Carro-Suárez, J.; Flores-Nava, I.; Flores-Salazar, F. (2011). Propuesta de una metodología para el análisis de engranes rectos aplicando ingeniería asistida por computadora. 10º Congreso Nacional de Mecatrónica, 3-4 de noviembre 2011 Jalisco, México. Asociación Mexicana de Mecatrónica A. C., 35-40. http://www.mecamex.net/anterior/cong10/trabajos/art09.pdf.

- Chaviano-Tovar, L.; Del Risco-Alonso, S.; Castelló-González, J.; Del Risco-Alfonso, R.; Ortega-Zayas Bazán, J. (2021). La capacidad del proceso como criterio de calidad en parámetros de piezas en bruto: Caso de estudio. Revista Cubana de Ingeniería, XII, 81-88. https://rci.cujae.edu.cu/index.php/rci/article/view/771.

- Contreras, C.; Meneses, J. (2015). Calibración y automatización de un proyector de perfiles usado para el control de calidad en la fabricación de perfiles plásticos extruidos. Revista Investigaciones Aplicadas, 9, 7-11. https://dialnet.unirioja.es/descarga/articulo/5230979.pdf.

- Cotaquispe, L. (2007). Influencia del ángulo de presión en el esfuerzo de flexión del pie de diente para engranajes cilíndricos de dentado recto exterior mediante el método de los elementos finitos. 8º Congreso Iberoamericano de Ingeniería Mecánica, 2007 Cusco, Perú. Pontificia Universidad Católica del Perú, 1-7. https://docplayer.es/82944562-8o-congreso-iberoamericano-de-ingenieria-mecanica-cusco-23-al-25-de-octubre-de-2007.html.

- Groover, M. (2010). Fundamentals of modern manufacturing. Materials, processes and systems, Hoboken, Estados Unidos., John Wiley & Sons, Inc. https://www.fcusd.org/cms/lib/CA01001934/Centricity/Domain/4529/Fundamentals%20of%20Modern%20Manufacturing%20Materials%20%20Processes%20and%20Systems%20%204th%20Edition.pdf

- Hayajneh, M.; Tahat, M.; Bluhm, J. (2007). A study of the effects of machining parameters on the surface roughness in the end-milling process. Jordan Journal of Mechanical and Industrial Engineering, 1, 1-5. http://jjmie.hu.edu.jo/files/001.pdf.

- ISO. (1996) Cylindrical gears for general engineering and for heavy engineering—Modules, ISO:54/1996, No., 1996.

- Kailuke, J.; Yenarkar, Y. (2013). Investigation of stresses in the thin rimmed spur gear tooth using fem. IJRET: International Journal of Research in Engineering and Technology, 2, 437-441. https://ijret.org/volumes/2013v02/i11/IJRET20130211064.pdf.

- Kalpakjian, S.; Schmid, S. R. (2008). Manufactura, Ingeniería y Técnología, México, Pearson Educación. www.pearsoneducacion.net/kalpakjian

- Moreno-Pino, M. R., Cobas-Aguilera, F. Y Suárez-Franco, L. E. (2021). Aplicación de metodología para la realización del control estadístico de la calidad de procesos. Revista de Desarrollo Sustentable, Negocios, Emprendimiento y Educación, 33-45. https://www.eumed.net/es/revistas/rilcoDS/25-noviembre21/calidad-procesos.

- Mott, R.; Vavrek, E. M.; Wang, J. (2018). Machine elements in mechanical design, New York, Estados Unidos, Pearson Education. https://ftp.idu.ac.id/wp-content/uploads/ebook/tdg/DESIGN%20SISTEM%20DAYA%20GERAK/Machine%20Elements%20in%20Mechanical%20Design.pdf

- Schey, J. (2002). Procesos de manufactura, México D.F., McGraw-Hill Interamericana Editores, S.A. de C.V. https://www.academia.edu/44631332/Procesos_De_Manufactura_John_A_Schey_3ra_Edici%C3%B3n

- Silva, P. J.; Alvares, A. J. (2020). Investigation of tool wear in single point incremental sheet forming. Jounal of Engineering Manufacture 234, 170-188. https://journals.sagepub.com/doi/abs/10.1177/0954405419844653&ved=2ahUKEwivuc255uPqAhWnnuAKHSvMB64QFjAAegQIBhAB&usg=AOvVaw11__F_KmtNFFfm-croFf8y.

- Tacle-Humanante, P. M.; Moya-Rodríguez, J. L.; Marty-Delgado, J. R. (2019). El índice de Robustez como parámetro para evaluar el comportamiento de las transmisiones por engranajes cilíndricos de dientes rectos. Ingeniería Mecánica, 22, 57-66. http://scielo.sld.cu/pdf/im/v22n1/1815-5944-im-22-01-57.pdf.

- Van-thoan, P.; Wen, G.; Yin, H.; LD, H.; Sy-Nguyen, V. (2015). Optimization Design for Spur Gear with Stress-Relieving Holes. International Journal of Computational Methods, 12, 1-11. http://search.ebscohost.com/login.aspx?direct=true&db=aps&AN=103686554&lang=es&site=ehost-live.

- Woodall, W. (2000). Controversies and Contradictions in Statistical Process Control. Journal of Quality Technology, 32, 341-350. https://www.tandfonline.com/action/showCitFormats?doi=10.1080%2F00224065.2000.11980013.