Análisis de sustratos aceptados para la co-digestión anaeróbica en la PTAR de Straubing, Alemania

Analysis of accepted substrates for anaerobic co-digestion at the WWTP in Straubing, Germany

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Copyright statement

The authors exclusively assign to the Universidad EIA, with the power to assign to third parties, all the exploitation rights that derive from the works that are accepted for publication in the Revista EIA, as well as in any product derived from it and, in in particular, those of reproduction, distribution, public communication (including interactive making available) and transformation (including adaptation, modification and, where appropriate, translation), for all types of exploitation (by way of example and not limitation : in paper, electronic, online, computer or audiovisual format, as well as in any other format, even for promotional or advertising purposes and / or for the production of derivative products), for a worldwide territorial scope and for the entire duration of the rights provided for in the current published text of the Intellectual Property Law. This assignment will be made by the authors without the right to any type of remuneration or compensation.

Consequently, the author may not publish or disseminate the works that are selected for publication in the Revista EIA, neither totally nor partially, nor authorize their publication to third parties, without the prior express authorization, requested and granted in writing, from the Univeridad EIA.

Show authors biography

La adopción de nuevas formas de producción energética es uno de los retos que enfrentan los países a nivel mundial debido al progresivo agotamiento de los combustibles fósiles. En ese sentido, la digestión conjunta de residuos orgánicos en Plantas de Tratamiento de Agua Residual (PTAR) ha ganado gran aceptación, pues ofrece una alternativa para usar diferentes tipos de biomasa para satisfacer necesidades energéticas y ayuda en la gestión de residuos y recuperación de nutrientes. Sin embargo, aceptar sustratos adicionales para la co-digestión, supone estudios fisicoquímicos minuciosos, puesto que sus características pueden influir tanto en la estabilidad del proceso como en la calidad y producción del biogás.

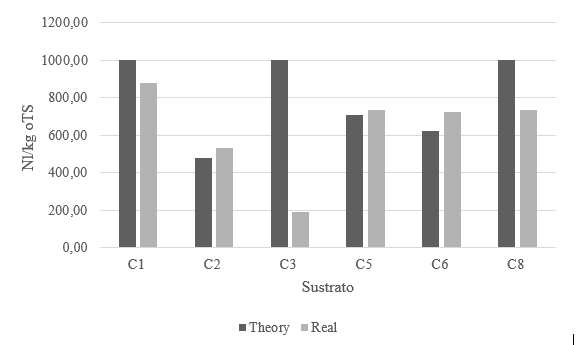

En concordancia con lo anterior, el presente trabajo implementó el método de estudio de caso a través del análisis descriptivo para evaluar los sustratos aceptados para la co-digestión anaeróbica en la PTAR de Straubing en Alemania (SER GmbH). Como resultado, se encontró que las grasas flotantes (C1) y la leche con inhibidores (C5) fueron los sustratos que presentaron mayor producción de biogás por unidad de masa tratada, 90 % por encima de los residuos de destilación y 70 % sobre los lodos crudos.

Estos hallazgos subrayan la importancia de seleccionar cuidadosamente los sustratos para la co-digestión en las PTAR, destacando la posibilidad de aprovechar recursos potenciales, como los evaluados en este estudio, para aumentar la eficiencia en la producción de biogás y, por lo tanto, promover una transición más efectiva hacia fuentes de energía sostenible en el contexto global.

La PTAR de Straubing en Alemania se convierte así en un ejemplo de las posibilidades que ofrece la co-digestión en la generación de energía sostenible y la gestión de residuos. La inclusión de grasas flotantes y leche con inhibidores como sustratos exitosos ilustra cómo la investigación y la implementación cuidadosa pueden optimizar el rendimiento de estas instalaciones.

Article visits 219 | PDF visits 111

Downloads

- Agustini, C.B., da Costa, M. & Gutterres, M. 2020. Tannery wastewater as nutrient supply in production of biogas from solid tannery wastes mixed through anaerobic co-digestion. *Process Safety and Environmental Protection*, 135, pp.38–45. https://doi.org/10.1016/j.psep.2019.11.037.

- Agustini, C.B., Meyer, M., Da Costa, M. & Gutterres, M. 2018. Biogas from anaerobic co-digestion of chrome and vegetable tannery solid waste mixture: Influence of the tanning agent and thermal pretreatment. *Process Safety and Environmental Protection*, 118, pp.24–31. https://doi.org/10.1016/j.psep.2018.06.021.

- Almeida, P. de S., Menezes, C.A. de, Camargo, F.P., Sakamoto, I.K., Varesche, M.B.A. & Silva, E.L. 2022. Thermophilic anaerobic co-digestion of glycerol and cheese whey – Effect of increasing organic loading rate. *Process Safety and Environmental Protection*, 165(April), pp.895–907. https://doi.org/10.1016/j.psep.2022.07.045.

- Angelidaki, I. & Ahring, B.K. 2000. Methods for increasing the biogas potential from the recalcitrant organic matter contained in manure. *Water Science and Technology*, 41(3), pp.189-194.

- Arhoun, B. 2017. Digestión y codigestión anaerobia de residuos agrícolas, ganaderos y lodos de depuradora [tesis doctoral, Universidad de Málaga]. Repositorio Institucional de la Universidad de Málaga (RIUMA). https://bit.ly/3UmK3U2.

- ATEMIS GmbH. 2014. Potential zur Annahme von Biomasse auf der Kläranlage Straubing. ATEMIS GmbH. https://bit.ly/3FJGrrd.

- Azarmanesh, R., Zarghami Qaretapeh, M., Hasani Zonoozi, M., Ghiasinejad, H. & Zhang, Y. 2023. Anaerobic co-digestion of sewage sludge with other organic wastes: A comprehensive review focusing on selection criteria, operational conditions, and microbiology. *Chemical Engineering Journal Advances*, 14(December 2022), 100453. https://doi.org/10.1016/j.ceja.2023.100453.

- Banks, C.J., Salter, A.M., Heaven, S. & Riley, K. 2011. Energetic and environmental benefits of co-digestion of food waste and cattle slurry: A preliminary assessment. *Resources, Conservation and Recycling*, 56(1), pp.71-79.

- Bareha, Y., Faucher, J., Michel, M., Houdon, M. & Vaneeckhaute, C. 2022. Evaluating the impact of substrate addition for anaerobic co-digestion on biogas production and digestate quality: The case of deinking sludge. *Journal of Environmental Management*, 319(March), 115657. https://doi.org/10.1016/j.jenvman.2022.115657.

- Barua, V.B. & Kalamdhad, A.S. 2019. Biogas production from water hyacinth in a novel anaerobic digester: A continuous study. *Process Safety and Environmental Protection*, 127, pp.82–89. https://doi.org/10.1016/j.psep.2019.05.007.

- Benito, C., Contreras, A., Higueras, M., Morón, M. del C. & Lebrato, J. 2018. IV Jornada de Investigación y Postgrado. In: A. Beltrán y M. Félix, eds. *Editorial Área de Innovación y Desarrollo*. https://doi.org/10.17993/ingytec.2018.34.

- Brew, A. & Arthur, R. 2010. Potential biogas production from sewage sludge: A case study of the sewage treatment plant at Kwame Nkrumah University of Science and Technology, Ghana. *International Journal of Energy and Environment*, 1(6), pp.1009-1016. https://bit.ly/3DWEfeH.

- Chávez, J.C., Velázquez Cigarroa, E. & Venegas Sandoval, A. 2022. Community interventions in the socioenvironmental context: good practices in the preservation of southern Mexico. *Revista Chapingo Serie Agricultura Tropical*, 2(1), pp.59-76. http://dx.doi.org/10.5154/r.rchsat.2022.03.0.

- Chow, W.L., Chong, S., Lim, J.W., Chan, Y.J., Chong, M.F., Tiong, T.J., Chin, J.K. & Pan, G.T. 2020. Anaerobic co-digestion of wastewater sludge: A review of potential co-substrates and operating factors for improved methane yield. *Processes*, 8(1), 39. https://doi.org/10.3390/pr8010039.

- Chynoweth, D.P., Owens, J.M. & Legrand, R. 2001. Renewable methane from anaerobic digestion of biomass. *Renewable Energy*, 22(1-3), pp.1-8.

- Deutsches Institut fur Normung E.V. 2001a. Characterization of sludges - determination of dry residue and water content (DIN EN 12880). https://www.din.de/de/mitwirken/normenausschuesse/fnla/veroeffentlichungen/wdc-beuth:din21:97210882.

- Deutsches Institut fur Normung E.V. 2001b. Characterization of sludges - Determination of the loss on ignition of dry mass (DIN SN 12879). https://www.din.de/de/wdc-beuth:din21:39205679.

- Deutsches Institut fur Normung E.V. 1990. Testing of gaseous fuels and other gases; determination of the components; gas chromatographic procedure (DIN 51872-4). https://www.din.de/de/mitwirken/normenausschuesse/nmp/veroeffentlichungen/wdc-beuth:din21:1562127.

- Deutsches Institut fur Normung E.V. 1998. Characterization of sludge - Determination of pH-value (DIN SN 12176). https://www.din.de/de/wdc-beuth:din21:12757670.

- Deutsches Institut fur Normung E.V. 2016. Fermentation of organic substances - substrate characterization, sampling, substance data collection, fermentation tests (VDI 4630). https://www.din.de/de/wdc-beuth:din21:244849582.

- Emilio, P., García, E., Lilia, A., Páez, C. & Álvarez, H.S. 2022. Evaluación técnico-económica de sitios de disposición final de RSU para aprovechamiento energético a pequeña escala. In: *Intervenciones y estudios socioambientales: Experiencias interdisciplinarias para la sustentabilidad*, pp.175–189. https://omp.siea.org.mx/omp/index.php/ompsieao/catalog/view/8/194/335.

- Escarraga, K. & Espinosa, N. 2020. Estrategias para la optimización del proceso de destilación en la planta de producción de alcohol anhidro a partir de la vinaza [Tesis de grado, Universidad de América]. Repositorio Institucional de la Universidad de América.

- Feng, L., Aryal, N., Li, Y., Jarle, S. & James, A. 2023. Developing a biogas centralised circular bioeconomy using agricultural residues - Challenges and opportunities. *Science of the Total Environment*, 868(January), 161656. https://doi.org/10.1016/j.scitotenv.2023.161656.

- Fernández-Rodríguez, M.J., de la Lama-Calvente, D., Jiménez-Rodríguez, A., Borja, R. & Rincón-Llorente, B. 2019. Influence of the cell wall of Chlamydomonas reinhardtii on anaerobic digestion yield and on its anaerobic co-digestion with a carbon-rich substrate. *Process Safety and Environmental Protection*, 128, pp.167–175. https://doi.org/10.1016/j.psep.2019.05.041.

- Groof, V. De, Coma, M., Arnot, T., Leak, D.J. & Lanham, A.B. 2021. Selecting fermentation products for food waste valorisation with HRT and OLR as the key operational parameters. *Waste Management*, 127, pp.80–89. https://doi.org/10.1016/j.wasman.2021.04.023.

- Fachagentur Nachwachsende Rohstoffe. 2010. Guía sobre el Biogás Desde la producción hasta el uso. FNR; Deutsches Biomasse Forschungs Zentrum (DBFZ). https://bit.ly/3zEapJr.

- Farinango, M. 2017. Redes y laboratorios de conocimiento, clave para alcanzar la cohesión latinoamericana. *Revista Investigium IRE: Ciencias Sociales y Humanas*, VIII (2), pp.7-10. doi:10.15658/INVESTIGIUMIRE.170802.01.

- Iweka, S.C., Owuama, K.C., Chukwuneke, J.L. & Falowo, O.A. 2021. Optimization of biogas yield from anaerobic co-digestion of corn-chaff and cow dung digestate: RSM and python approach. *Heliyon*, 7(11), E08255. https://doi.org/10.1016/j.heliyon.2021.e08255.

- Krich, K., Augenstein, D., Batmale, J.P., Benemann, J., Rutledge, B. & Salour, D. 2005. Biomethane from Dairy Waste: A Sourcebook for the Production and Use of Renewable Natural Gas in California. *US Environmental Protection Agency*, pp.37-45.

- Kunatsa, T. & Xia, X. 2022. A review on anaerobic digestion with focus on the role of biomass co-digestion, modelling and optimisation on biogas production and enhancement. *Bioresource Technology*, 344(PB), 126311. https://doi.org/10.1016/j.biortech.2021.126311.

- Mao, C., Feng, Y., Wang, X. & Ren, G. 2015. Review on research achievements of biogas from anaerobic digestion. *Renewable and Sustainable Energy Reviews*, 45, pp.540-555.

- Martínez, C. 2006. El método de estudio de caso: estrategia metodológica de la investigación científica. *Pensamiento & Gestión*, 20, pp.165-193. https://bit.ly/3h827Dh.

- Mata-Alvarez, J., Dosta, J., Romero-Güiza, M.S., Fonoll, X., Peces, M. & Astals, S. 2014. A critical review on anaerobic co-digestion achievements between 2010 and 2013. *Renewable and Sustainable Energy Reviews*, 36, pp.412–427. https://doi.org/10.1016/j.rser.2014.04.039.

- Montoya Campuzano, O.I., Quintero Dallos, J.A., Sánchez Toro, O.J. & Cardona Alzate, C.A. 2020. Parámetros de calidad de producción de biogás a partir de pulpa de café. *Revista Facultad de Ingeniería*, 29(54), pp.1-13. https://doi.org/10.19053/01211129.v29.n54.2020.10984.

- Nizami, A.S. & Murphy, J.D. 2010. What type of digester configurations should be employed to produce biomethane from grass silage? *Renewable and Sustainable Energy Reviews*, 14(6), pp.1558-1568.

- Nwokolo, N., Mukumba, P., Obileke, K. & Enebe, M. 2020. Waste to energy: A focus on the impact of substrate type in biogas production. *Processes*, 8(10), 1224. https://doi.org/10.3390/pr8101224.

- Pessuto, J., Scopel, B.S., Perondi, D., Godinho, M. & Dettmer, A. 2016. Enhancement of biogas and methane production by anaerobic digestion of swine manure with addition of microorganisms isolated from sewage sludge. *Process Safety and Environmental Protection*, 104, pp.233–239. https://doi.org/10.1016/j.psep.2016.08.020.

- Reyes, I., Díaz, J. & Horváth, I. 2015. Anaerobic Biodegradation of Solid Substrates from Agroindustrial Activities - Slaughterhouse Wastes and Agrowastes. In: R. Chamy, F. Rosenkranz y L. Sole, eds. *Biodegradation and Bioremediation of Polluted Systems*. https://doi.org/10.5772/60907.

- Sillero, L. & Solera, R. 2022. Improvement of the anaerobic digestion of sewage sludge by co-digestion with wine vinasse and poultry manure: Effect of different hydraulic retention times. *Fuel*, 321(March), 124104. https://doi.org/10.1016/j.fuel.2022.124104.

- Straubinger Entwässerung und Reinigung. n.d. Energie und Reststoffverwertung. Consultado el 13 de mayo de 2022. https://bit.ly/3U3aOgK.

- Tolessa, A., Goosen, N.J. & Louw, T.M. 2023. Probabilistic simulation of biogas production from anaerobic co-digestion using Anaerobic Digestion Model No. 1: A case study on agricultural residue. *Biochemical Engineering Journal*, 192(January), 108810. https://doi.org/10.1016/j.bej.2023.108810.

- Ward, A.J., Hobbs, P.J., Holliman, P.J. & Jones, D.L. 2008. Optimisation of the anaerobic digestion of agricultural resources. *Bioresource Technology*, 99(17), pp.7928-7940.

- Weiland, P. 2010. Biogas production: current state and perspectives. *Applied Microbiology and Biotechnology*, 85(4), pp.849-860.

- Zhang, D., Duan, N., Tian, H., Lin, C., Zhang, Y. & Liu, Z. 2018. Comparing two enhancing methods for improving kitchen waste anaerobic digestion: Bentonite addition and autoclaved de-oiling pretreatment. *Process Safety and Environmental Protection*, 115, pp.116–124. https://doi.org/10.1016/j.psep.2017.09.011.

- Zhao, J., Li, Y. & Zhang, Z. 2023. Hydraulic retention time and pressure affect anaerobic digestion process treating synthetic glucose wastewater. *Bioresource Technology*, 370(October 2022). https://doi.org/10.1016/j.biortech.2022.128531.